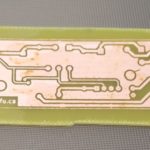

I’ve been meaning to make a more permanent power supply board for the nixie project, so over the last couple of weeks I decided on what I wanted. Transformer input, which meant a bridge  rectifier, couple of caps, the mount for the DC-DC power supply from tayloredge, a regulator to drive a 5v ATtiny later on, along with a FET to turn on and off the high-voltage output. So I plunked it all into KiCAD (I’m getting better at it), and this is what I came up with. I also decided, I’d try my hand at etching it myself, and take advantage that Misses Boffin had recently purchased a heat press. Maybe I’d be able to do better heat transfers from my Brother laser printer — which are notoriously bad for toner transfer due to a higher temperature toner and fuser than most others (like HP). Well, I played with all sorts of backing, all sorts of temps and time, and came up with pretty much what I had done in the past; old glossy magazine paper. The glossy magazine paper, along with about a minute at 375°F in the heat press gave a pretty good results. After a 10 minute soak in water to pull the paper off, it turned out pretty well. In fact very well, I’ll probably do a lot more this way now that I have a reliable transfer method. Also, I made sure to ground fill the board, so I’ll use less ferric chloride in the future (not that it’s that expensive).

rectifier, couple of caps, the mount for the DC-DC power supply from tayloredge, a regulator to drive a 5v ATtiny later on, along with a FET to turn on and off the high-voltage output. So I plunked it all into KiCAD (I’m getting better at it), and this is what I came up with. I also decided, I’d try my hand at etching it myself, and take advantage that Misses Boffin had recently purchased a heat press. Maybe I’d be able to do better heat transfers from my Brother laser printer — which are notoriously bad for toner transfer due to a higher temperature toner and fuser than most others (like HP). Well, I played with all sorts of backing, all sorts of temps and time, and came up with pretty much what I had done in the past; old glossy magazine paper. The glossy magazine paper, along with about a minute at 375°F in the heat press gave a pretty good results. After a 10 minute soak in water to pull the paper off, it turned out pretty well. In fact very well, I’ll probably do a lot more this way now that I have a reliable transfer method. Also, I made sure to ground fill the board, so I’ll use less ferric chloride in the future (not that it’s that expensive).

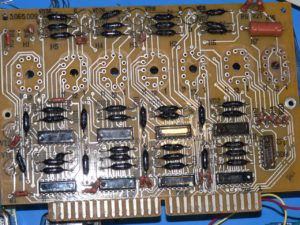

On to etching; I use two pyrix dishes, a larger and a smaller one. Put some hot water (just off the boil in the outer), and then ferric chloride in my inner pyrex dish, (silly me didn’t  take a photo), and it took about 6-7 minutes to etch. The moment of truth, rub off the toner (I use a stainless steel dish scrubber to pre-clean and post-clean the board) and what

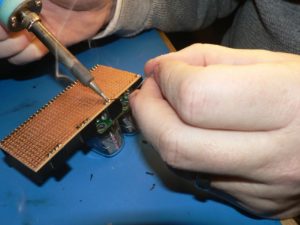

take a photo), and it took about 6-7 minutes to etch. The moment of truth, rub off the toner (I use a stainless steel dish scrubber to pre-clean and post-clean the board) and what  does it look like; it looks great! Drilling is a breeze, I bought this tiny drill press from Rio Grande a few years back, and it does a great job on PCBs. It has pathetic torque, but when you’re drilling a 0.9mm hole, you don’t need it. With my aging eyesight, I tried using the optivisor to get a better look while drilling, but in this case it doesn’t work that well, as you have to get insanely close to get anything in focus, so I ended up just doing most of it using the bad

does it look like; it looks great! Drilling is a breeze, I bought this tiny drill press from Rio Grande a few years back, and it does a great job on PCBs. It has pathetic torque, but when you’re drilling a 0.9mm hole, you don’t need it. With my aging eyesight, I tried using the optivisor to get a better look while drilling, but in this case it doesn’t work that well, as you have to get insanely close to get anything in focus, so I ended up just doing most of it using the bad  eyeball method. A few test fits along the way, and it was definitely in the realm of ‘close enough’. Finishing the board I realized I was using the same saw and the same file that I would use to finish veroboard projects from nearly 40 years ago. The saw is an engineering metalwork project from my O-level days (Tin-Man will likely recognize it), and the file was inherited from my grandfather’s stash of tools in the mid-70s.

eyeball method. A few test fits along the way, and it was definitely in the realm of ‘close enough’. Finishing the board I realized I was using the same saw and the same file that I would use to finish veroboard projects from nearly 40 years ago. The saw is an engineering metalwork project from my O-level days (Tin-Man will likely recognize it), and the file was inherited from my grandfather’s stash of tools in the mid-70s.

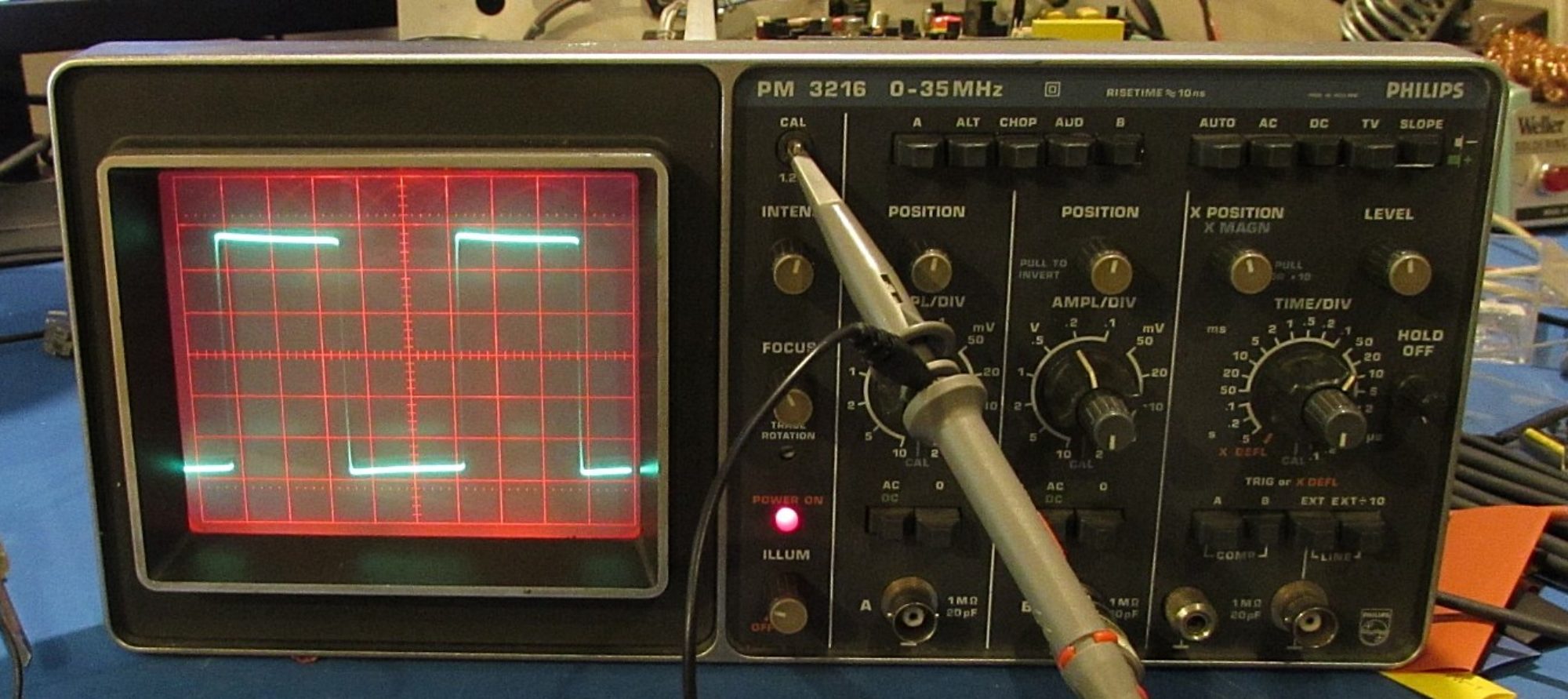

The final result turned out really well. I managed to not get any pin-outs wrong, the regulator is perfectly at the edge of the board to allow it to  mount to the back panel for heatsinking, and most importantly it worked first time. Just need to get a 12V transformer from Lee’s at some point, and fit all of it (transformer, PSU board) along with a switch and fuse and I’ve got the supply all done for my mystery nixie project.

mount to the back panel for heatsinking, and most importantly it worked first time. Just need to get a 12V transformer from Lee’s at some point, and fit all of it (transformer, PSU board) along with a switch and fuse and I’ve got the supply all done for my mystery nixie project.

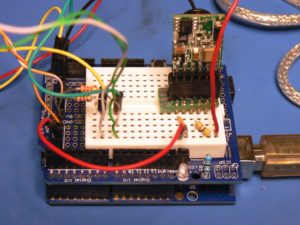

I also spent some time over the weekend playing on another project, but that will be another post, when the last of the parts for that arrives.