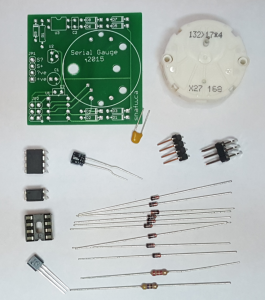

Well, the first of two orders of PCBs came back just before I went away on vacation. The first lot I had discussed in my previous blog entry, and was a remake of my stepper gauge project that I sell on Tindie. As my previous experience with OSHPARK, the service is superb. About a 18 day turnaround including crossing the border, free shipping to Canada (not many include that), plus a nice “PERFECT PURPLE PCBS” sticker, which I’ve adorned to my electronics toolbox. If you need a quick(ish) PCB service for a prototype, OSHPARK is pretty close to perfect.

Apparently I did my homework well, because the X27.168 stepper package outline (I found one on the net, but tweaked it further) fits like a glove, unlike my previous revision where I had relied on someone else’s package file and every board required some drilling to fix layout holes. It all looks very nice, and I love the purple, but sadly I didn’t get a chance to assemble one before I left on 3 weeks holiday, all I managed to do is file off the mouse-bites that they used to panelize it.

Apparently I did my homework well, because the X27.168 stepper package outline (I found one on the net, but tweaked it further) fits like a glove, unlike my previous revision where I had relied on someone else’s package file and every board required some drilling to fix layout holes. It all looks very nice, and I love the purple, but sadly I didn’t get a chance to assemble one before I left on 3 weeks holiday, all I managed to do is file off the mouse-bites that they used to panelize it.

Once I had become familiar with KiCad, there was no stopping me, so I had also slapped together a little hybrid surface-mount/through-hole project that I’ll use for an electronics class I’ll be teaching in the near future, and ordered them from a company I had read about on EEVBLOG called DIRTYPCBS. When I return, I’m hoping my other PCBs will be sitting waiting for me. I read about this service on EEVBLOG, and it has a few advantages over OSHPARK. Firstly the price; as they’re in Asia (Hong Kong), the price is amazing (US$24 incl shipping for 10 boards 10cm x 5cm). Secondly you have a lot more options such as PCB thickness, soldermask colour, etc etc. I’m quite excited that DIRTYPCBs might become my go-to circuit board provider for anything more than a couple of small samples. Also this board will be my first real foray into SMD (just some 0805s, SOT23 and small LEDs). I’ve avoided SMD as I lack the tools (and eyesight), but wow are the parts ever cheap, one dollar will buy you 300 resistors, or 100 capacitors, or 100 FETs; just incredible. I’ll still try assembling with the old weller iron, but I’m curious to try paste and and a hot air gun.

Also, I did some reading (and viewing on YouTube) of people doing hybrid hot/cold transfer for laser printer transfers. I have made single sided PCBs using the laser printer transfer method and an iron, but it took a fair bit of experimenting to discover that with my brother laser printer that only glossy magazine paper really worked for laser printer transfers. Two things have changed; one I discovered people are using a mixture of acetone/isopropyl alcohol on the PCB surface prior to transfer to slightly disolve the toner, and secondly Misses Boffin has purchased a heat press (for doing vinyl transfer), so I have a better heat press with likely more even heating/pressure.

Hmm, I wonder if I can just cut a PCB mask using a silhouette vinyl cutter. Must look into that, that might work too.

Well; I finally put the rest of my little stepper motor gauge project together and listed it on Tindie. Once they approve it, you should be able to find it by following the link at the top of the page to our Tindie Store.

Well; I finally put the rest of my little stepper motor gauge project together and listed it on Tindie. Once they approve it, you should be able to find it by following the link at the top of the page to our Tindie Store.