Woke up yesterday morning to a gas furnace that wouldn’t light. It’s an older Bryant (Carrier), but it has been working well, and we don’t burn enough gas over the year that the $5,000 investment in a new one would be worth it.

Step 1, let’s see what is and isn’t working.

- Main fan seems to be working on power up – CHECK

- Inducer fan is running prior to attempting to light – CHECK

- Ignitor lights (glows) – CHECK

- Gas valve isn’t opening – THERE’S YOUR PROBLEM MURIEL

It doesn’t appear to open the gas valve – Hmmm. Now all of the connections run from the various parts to the control board on an edge connector, it couldn’t be that easy could it? Out with the Deoxit, quick spray, no difference.

Next, let’s buzz out the gas valve. Is there resistance? Yep, should be good. Disconnect the gas valve from the board and try it straight across the 24V from the transformer that powers the circuit board, and the gas valve opens.

That means something is up on the main board. Seems to be a pretty popular board (Carrier CES0110057-01). to the point where there’s a company (ICM Controls) making a compatible board ICM281, for a pretty decent price — if you happen to live in the USA — sadly it’s nearly double here in Canada; over $400, but still better than the $700 the furnace guys all quoted.

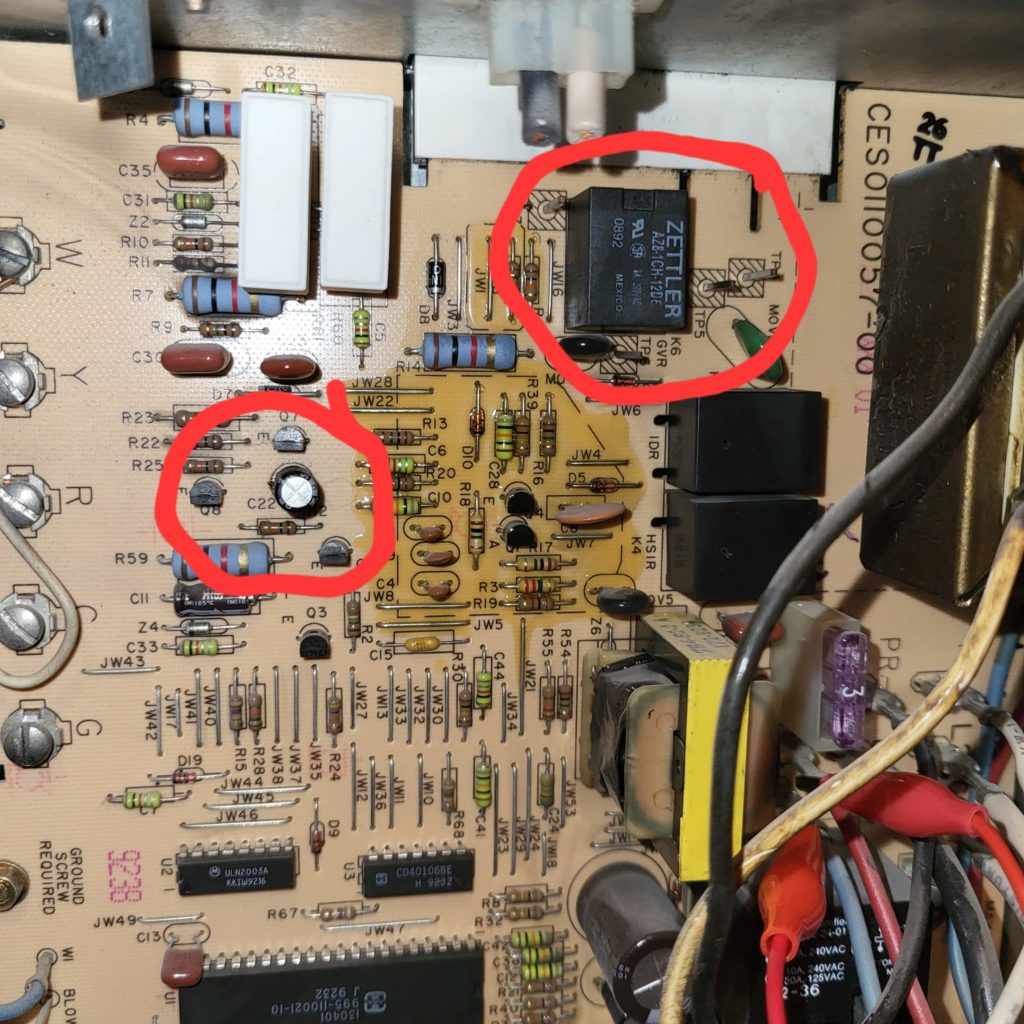

My initial guess is that it’s the relay, well relays are cheap, I even have one in the parts bins I could use, so let’s give that a whirl before we drop $400 on a new board. Pulled the board out, desoldered the relay (Zettler, a brand I’d never heard of before), and tried it on the bench. click click click, the relay is just fine. Damn.

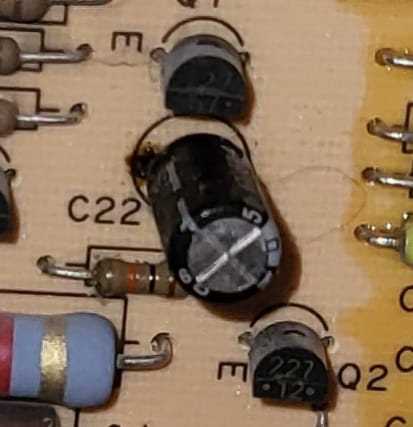

Let’s make sure everything driving it is OK. Traced the connections back to a capacitor, and hey, what’s this, looks like maybe this capacitor has let go after 25yrs. Desolder the cap, and sure enough there’s electrolyte leaking out the bottom. Clean off the board with some isopropyl, and drop in a new cap from the parts cabinets (47μF/50V). A new 5¢ capacitor certainly isn’t going to do any harm.

Re-installed the control board, and what do you know, it fires right up first time. YAY !

Now off to put on a nice cup of tea and write a blog post about this….

Time sure flies. I haven’t posted here in a while, but I thought I’d upload a few pictures of the most recent hack around the bench. Took my old Radio ‘Battery Eliminator’ (12V, 3A), and converted it into a constant voltage/constant current supply using a little module I got from China (

Time sure flies. I haven’t posted here in a while, but I thought I’d upload a few pictures of the most recent hack around the bench. Took my old Radio ‘Battery Eliminator’ (12V, 3A), and converted it into a constant voltage/constant current supply using a little module I got from China (